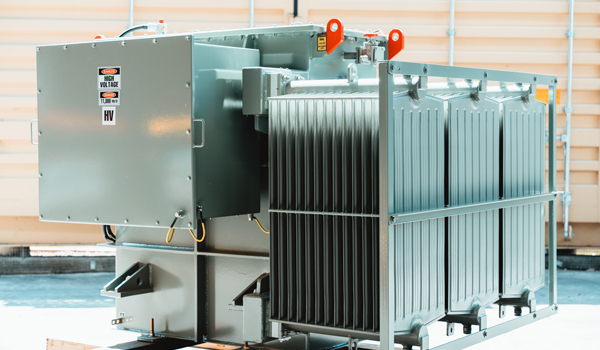

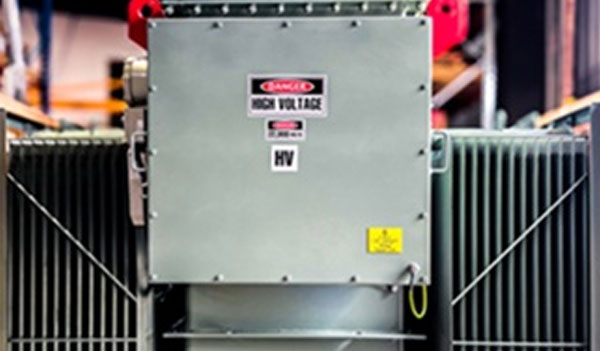

An overview of a complex customer transformer made to fit existing transformer specifications, delivered to Agnico Eagle in Victoria....

Read more

Celebrating 50 Years of Engineering Excellence

With over 50 years of engineering expertise, Hunter Transformers has established itself as a trusted provider of high-quality transformer solutions across Australia.

Specialising in custom-engineered dry-type, oil-filled, and gas-insulated transformers, as well as kiosk substations, CTs, VTs, and reactors, our company delivers tailored systems designed to meet the unique demands of sectors including infrastructure, mining, renewables, defence, and rail.

Contact UsThe Hunter Standard

At Hunter Transformers, quality isn’t just a goal—it’s our guarantee. Whether manufacturing locally in Sydney or managing production through our long-standing international partners, our Australian-based team applies the same uncompromising standards at every stage. We conduct regular supplier audits, enforce strict quality control checkpoints, and maintain direct, engineer-to-engineer communication to ensure every transformer we deliver meets both regulatory requirements and your unique project specifications. This hands-on, detail-driven approach is what sets us apart—and what our clients trust.

Our commitment to quality, safety, and compliance is underpinned by a suite of industry-recognised accreditations. All our transformer systems are manufactured and tested in accordance with Australian Standards.

Padmounted Kiosks

Providing electrical & space efficient solutions for power distribution, whilst maintaining aesthetics.

Distribution Transformers 11kV - 66kV

Premium Grade transformers designed to reliably step voltage up or down across high voltage networks

Padmounted Substations & LV/MV Switchgear

Safe & Compact Solutions for controlling, protecting and isolating sections of the electrical distribution network

Neutral Earthing Transformers

Providing a stable neutral point and grounding for medium voltage power systems

Ring Main Unit's (RMU's)

Providing reliable switching and fault detection & tripping, at the junction of the load's circuit

Our Production

Our engineered solutions are trusted across a wide range of critical industries.

Distribution Transformers 3.3 - 33kV

Hunter Transformers supply Medium Voltage (MV) Distribution Transformers that provide reliable and efficient voltage transformation for a wide range of applications.

Power Transformers (ONAN/KNAN) 66 - 330kV

Our power transformers use insulating oil to both cool and electrically insulate its internal components. Both ONAN/KNAN types offer reliable, low-maintenance cooling through passive convection.

Enhance Protected Transformers (EPTs)

We are involved in the design of power transformers up to 20MVA and the local manufacture of power transformers up to 500kVA. We work according to client demands, site conditions and referred standard, and comply with IE

Our Team

Mike Lush

Head of Business Development

Business Development Manager leveraging 20+ years of OEM expertise to connect sales, engineering, and manufacturing, delivering innovative electrical solutions to national and international markets.

Steve Kendall

Sales Manager

Bachelor of Commerce graduate with global experience in hospitality, construction, and high-pressure operations. Passionate about teamwork, problem-solving, and creating lasting positive change.

Bill Song

Principal Engineer

Master of Electrical Engineering graduate (UNSW, 2011) with specialised expertise in transformer performance and design. As Principal Engineer, Bill excels in translating complex customer requirements into precise, high-performing solutions that meet and exceed expectations

Aristos Gampierakis

Project Manager

Project Manager with an electrical engineering background, delivering turnkey transformer solutions through expert coordination, quality assurance, and on-time project delivery.

Latest Projects

Siemens SI 7 MVA Tasnetworks STATCOM Transformers

When Siemens Ltd required a specialized transformer for TasNetworks' STATCOM system in Tasmania, Hunter Transformers was engaged to deliver two high-performance 7 MVA 22/0.630 kV dual-secondary units engineered for grid stability and voltage support...

Read moreWoolooga Solar Installation, QLD

As part of the Lightsource bp renewable energy initiative, Hunter Transformers has been engaged to support the delivery of critical infrastructure for the Woolooga Solar Installation in Queensland...

Read moreGet in Touch

Please use the contact form below to get in touch or feel free to give us a call.